Products

The compact shredder for wood chip production

Optimal cost/performance ratio

Reliable and sturdy

Energy-efficient drive concept

Mature cutting system

Customized system solutions

Rated capacity: 14.8 - 24.8 hp | 11 - 18.5 kW

Feed opening: 24.6" x 31.2" | 624 x 792 mm

Fraction sizes (based on the screen): 0.6" - 1.2" | 15 - 30 mm

Maximum throughput capacity: 2 srm/h

Customers love our single shaft wood shredder due to its robust construction and excellent price-performance ratio. The high-performance shredder drive concept, a powerful horizontal pusher, and the tried and tested UNTHA cutting system ensure that the shredding process remains dependable. The homogeneous end-product produced by the shredder is ideal for incineration in a wood chip heating system or manufacturing wood briquettes. This shredder saves substantial energy costs due to its low drive capacity and integrated idle shut-down function.

The LR630 is one of the most popular shredders used by cabinet makers and carpenters. Thanks to technology like the offset rotor bearing, proven and reliable gear damping, and special cutting tools, this wood shredder is low maintenance and has a long service life. A further advantage of the shredder is the horizontal pusher, which presses the waste wood against the rotor with the blades. The hydraulics unit is placed in the machine housing to save space, where it is also protected from dust and dirt. Automatic foreign object detection, including a shut-down system, protects the cutters from damage. In addition, the machine features an automatic reverse function which prevents motor overload during shredding.

Energy efficiency is an important characteristic of the LR630 shredder. The proven cutting system ensures wood is shredded efficiently and reliably. The shredder is available starting with a drive capacity of 11 kW. If the machine stands idle for more than three minutes, it will shut down automatically. This saves energy whilst simultaneously reducing the operating costs of your wood working plant.

The LR630 shredder is especially suitable for shredding hardwood, chipboard, veneers, MDF sheets, and cardboard into valuable wood chips as fuel and for further processing.

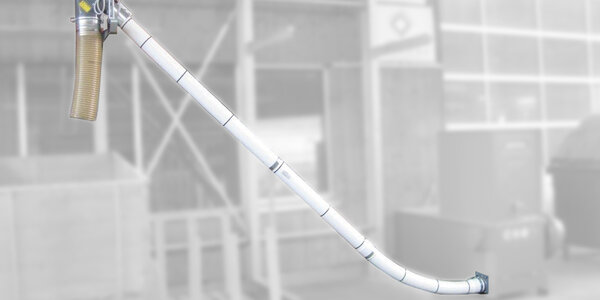

Each of our wood shredders is customized to your needs. The machines can also be equipped with a metal separator, a conveyor system, or a customized hopper which optimizes your wood chip transportation and processing. We offer comprehensive, single-source solutions!

Test this shredder with your own materials in our state-of-the-art test centre. Alternatively, we will take our wood shredder to your premises and you may test the machine in real-life operating conditions.

Depending on your requirements, we offer custom-made accessories for this shredder.

Shredding residual timber with nails or screws is no problem for our shredders. Pipe magnets are commonly used in extraction situations to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.