Directly from the manufacturer - developed with the highest possible standards in Austria

With a wide range of slow-speed wood waste shredders, UNTHA offers robust, reliable, and powerful chipping and shredding solutions for the American wood products industry. Our shredders provide exceptional output, whether employed as an integrated part of a complete system or used on their own. UNTHA also provides a range of conveyor solutions for materials handling, including conveyor belts, screw conveyors, and tiltable loading beds for especially long items. UNTHA is your one-stop source for material handling and shredding. The benefits of getting everything right from the manufacturer speak for themselves:

All-in-one solutions from a single source

Quick and easy purchasing with no detours

Affordable pricing

Comprehensive service

3-year warranty on all wood shredders

You do not want to read everything? Jump directly to the points that are relevant for you:

Wood waste is a by-product of any woodworking or wood processing activity. When it comes to the manufacture of products and parts, wood waste is much more than waste. It is a valuable material that, if processed properly, can be reused to generate revenue. With efficient shredding technology, wood waste can be transformed into wood chips that can be burned in wood chip heating systems, further processed into wood pellets and wood briquettes, used to make chipboard panels, or simply turned into low-volume materials that are cheaper to transport.

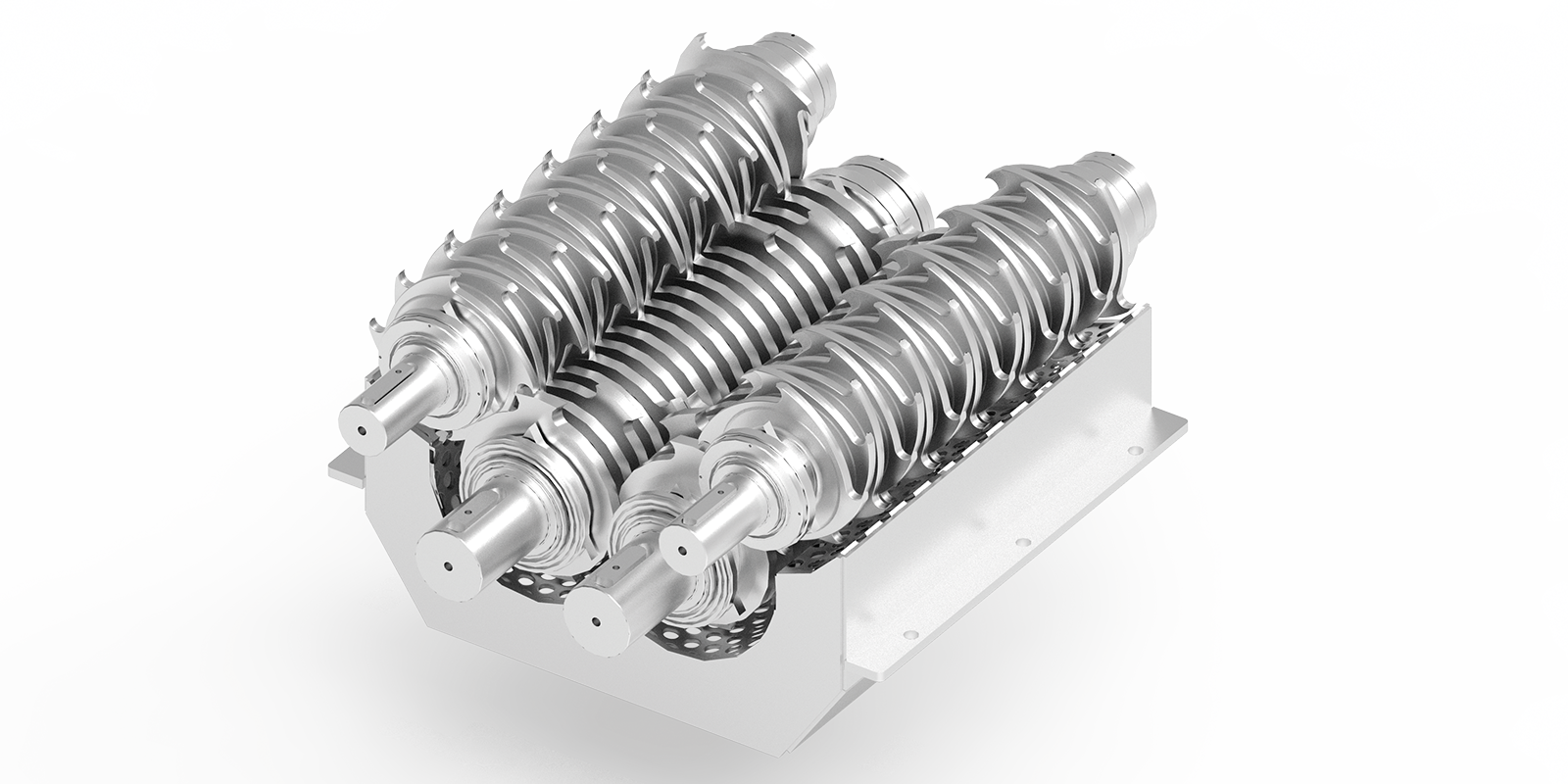

UNTHA offers individual solutions for all your wood waste shredding needs, whether softwood, hardwood, splinters, pallets, off-cuts, bark, chipboard panels, or veneers. Our wide selection of one- to four-shaft shredders comes in a variety of widths, rotor diameters and drive powers for shredding your wood waste .

Why is uniform chip size important?

UNTHA wood grinders produce consistently uniform chips sizes, which makes the chips much more beneficial in a number of ways. Chip size is especially important for ensuring that wood chip heating systems function in a safe and problem-free manner. Uniform size is also important for conveyance by means of screw conveyors as well as for manufacturing briquettes and pellets. Our industrial wood shredders are capable of producing particle sizes that generally range from 12 to 80 mm.

UNTHA waste wood shredders are best suited for businesses in the wood products industry, including sawmills, furniture and flooring manufacturers, manufacturers of prefabricated wood elements, and much more. No matter what duration you require: from a couple hours to non-stop operation with multiple shifts.

Why UNTHA?

13,000 UNTHA shredders are used on a daily basis

3-year warranty on all wood shredders

More than 50 years of experience in shredding and chipping technology

Tailor-made system solutions direct from a single manufacturer

Comprehensive customer service

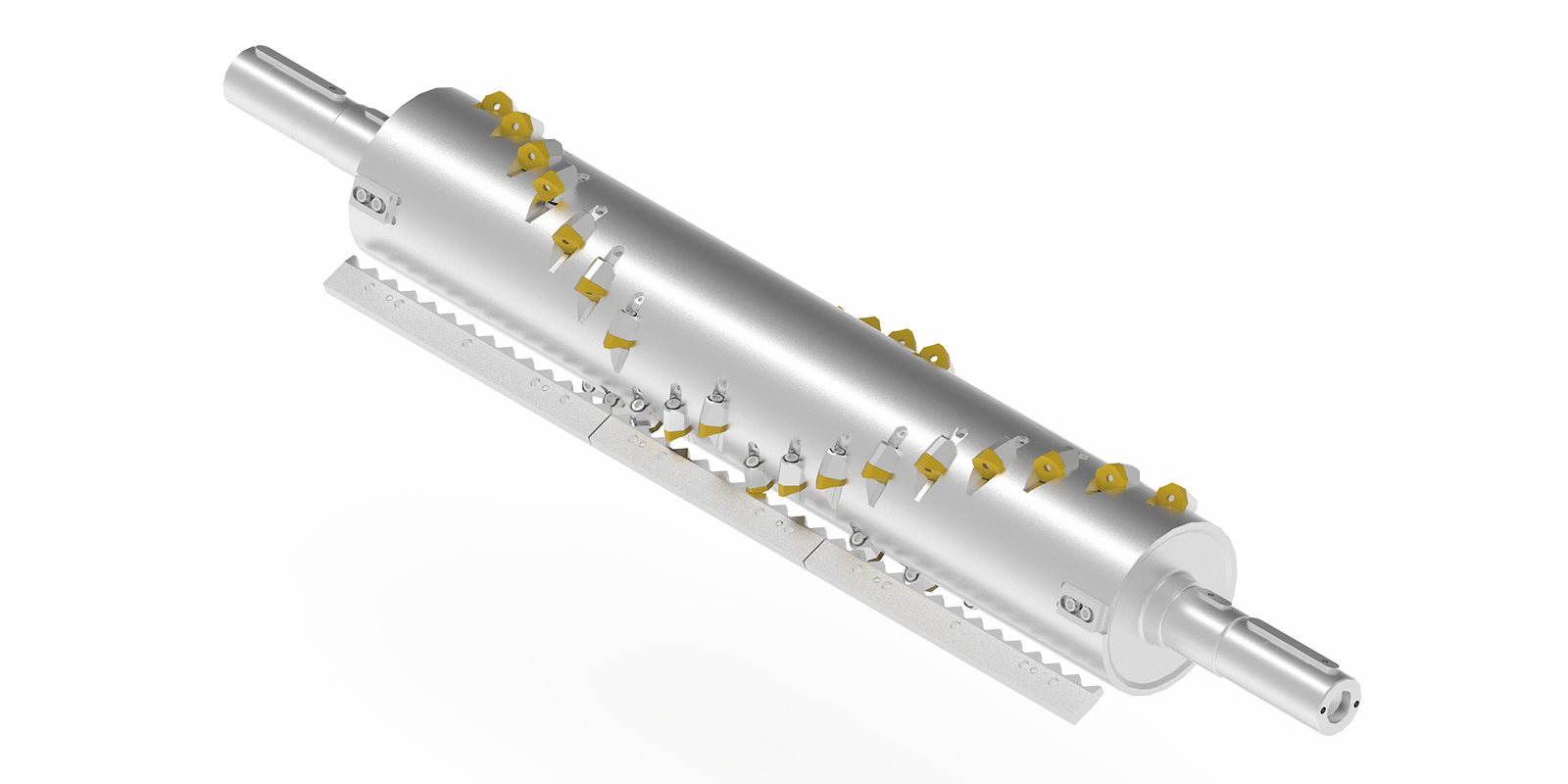

The unique shape of the indexable inserts makes for a “cut-as-you-pull” effect, which means that the unit requires less power and achieves a higher throughput.

The smooth, full-steel rotor enables the indexable inserts to dig deeper into the material than a highly profiled rotor, resulting in excellent material feed-in.

Each side has a long lifespan, making the cutting system particularly low maintenance. The flat shape of the blade ensures a higher throughput, reduces wear and tear and is not susceptible to non-shreddables made of metal.

The cutting system may be customised to suit the input material.

The cutting system is particularly resistant towards metal non-shreddables and stands out for its low dust and noise production.

The cutting system has a service life of several thousand hours.

We have nothing but praise for our unit, and several other carpentry shops have asked us about it. We were more than happy to recommend UNTHA to them.

Gerhard Kienpointner

Managing Director

We would like to talk to you about the right solution for your requirements. Afterwards, we will be happy to provide you with a tailor-made offer. Just fill out the form and we will contact you, or simple call us: +1 603 601 2304