UNTHA 4-shaft technology

UNTHA's latest technical development made headlines back in spring 2024 when the Austria-based company unveiled the advanced generation of its RS class. The news marked the latest iteration of the world-renowned four-shaft shredders, which have been continuously developed since their initial market launch many decades ago. And the market has responded positively: shortly after the presentation at IFAT, the first RS orders were received from customers in numerous countries.

Here is a summary of the 10 advanced features and design modifications that will enable customers worldwide to benefit even more from the RS class in the future:

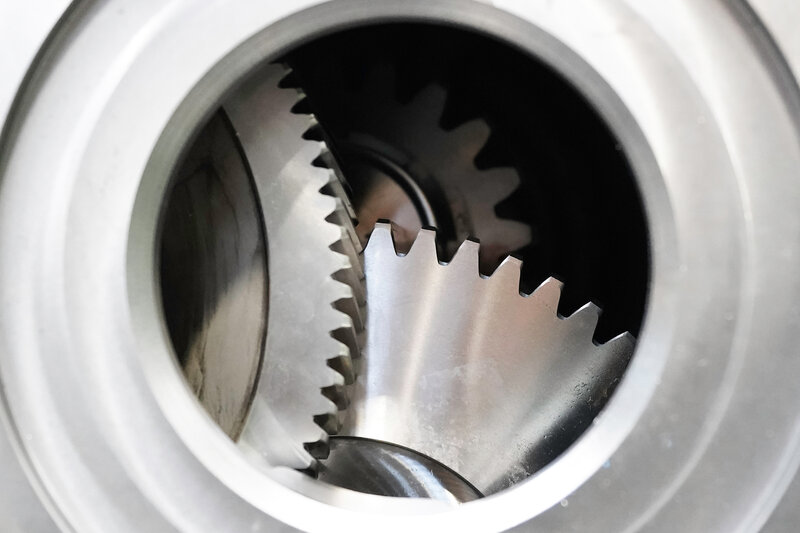

1. Throughput capacity plays a significant role. For this reason, minor adjustments have been made to the perforated screen body and the symmetry of the cutting system to reduce blockages and improve the shredder's capacity.

2. The shredders in the RS class have a direct drive. This means there are fewer wear parts, making maintenance even easier and more cost-effective.

3. UNTHA shredders are already known for their uptime. Nevertheless, improvements are continuously being made to the machines. UNTHA's dedicated research and development team has improved the integrated quick-change screen system, reducing the changeover time by 30%. This means that machine maintenance takes even less time, leaving more time for shredding.

4. Ergonomic service and maintenance access have been ensured to reduce working times and relieve the strain on operators. Care has also been taken to ensure that work on the machine can be carried out using standard tools.

5. The reduction of noise emissions is an essential aspect for UNTHA. The new generation of the RS class is 8% quieter, producing only 74 dB(A).

6. While performance is naturally a priority, UNTHA also pays attention to the aesthetics of its shredders. A fresh new design – with customizable hopper colors – ensures an eye-catching appearance. But this refresh is about more than just visual appeal. For example, the LED light bar shows the shredder's operating status at a glance – another feature introduced to support customers in their daily work.

7. The RS control panel has also been redesigned as part of the UX update. The improved touchscreen display, with a redesigned user interface and an integrated operating hours counter, makes fault diagnosis and troubleshooting easier. The control system now achieves performance level d according to EN 13849-1.

8. The ability to proactively monitor the condition of the shredder has long been popular with XR and ZR customers. Now, the intuitive, data-driven UNTHA GENIUS software solution is also available for four-shaft shredders.

9. The RS series is designed for particularly challenging waste and recycling streams and can be equipped with the UNTHA “Teck Pack” – a range of optional features – if required. These include more durable mechanical seals to protect the bearings, pre-tensioned cutting discs to improve the shredder's resistance to foreign objects, and shaft ventilation to reduce contamination. Several design features are also available, each individually configurable to meet specific customer requirements.

10. The advanced generation of the RS series incorporates countless small but powerful developments – all designed to offer customers more performance, more application versatility, more uptime, and more efficiency, while keeping costs under control.

Would you like to see the new features of the RS series for yourself? − Feel free to contact us for a personal consultation or a live demonstration: click here for our contact form.

5,000 units from UNTHA's RS series are already in use worldwide to recycle materials such as electronic scrap, hard drives, production waste, plastics, batteries, aluminum profiles, and household appliances. These shredders are used for volume reduction, material separation, and shredding to a homogeneous particle size. This achieves optimal recycling and recovery performance for customers. As a globally active group of companies, UNTHA has sold more than 15,000 shredders since its foundation.