References

The Royal Mint was looking for a new business area to counteract the decline in cash usage and shrinking demand for coins. In collaboration with partner companies, The Royal Mint developed a new process for recovering precious metals from electronic scrap. Three UNTHA RS30 shredders are part of this plant and serve as the starting point for the entire processing process.

As the official manufacturer of British coinage, The Royal Mint can look back on a history spanning more than 1,100 years, making it the oldest company in the United Kingdom. Throughout its history, the company has always stood for precision, technical excellence, and an unwavering commitment to quality—from the production of national coins and commemorative medals to the provision of investment opportunities in gold and silver.

With the declining demand for labor in traditional coin production, The Royal Mint recognized the need to diversify its business activities. Over the years, the United Kingdom has become the second largest producer of electronic waste per capita. This presented The Royal Mint with an opportunity to reduce exports of discarded electronic equipment and keep the value of the precious metals it contains in the country. A new process was developed, and a corresponding plant was planned. As a starting point for recycling, suitable shredders were sought that were particularly suitable for shredding circuit boards.

REQUIREMENTS

Efficient and precise shredding

Robust machines for e-waste

Seamless integration into the processing line

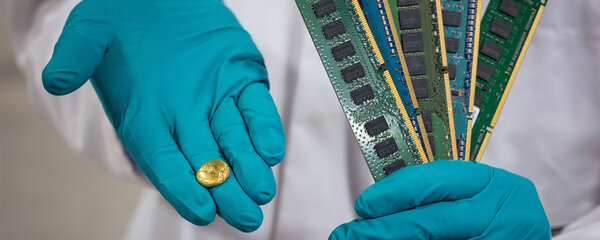

The plant is an industry first, recovering precious metals from electronic devices. At the start of the process are three UNTHA shredders – model RS30. They shred the circuit boards into precise particles and ensure that metals and non-metals can be separated for further treatment. The material goes through a series of complex steps. Base metals are extracted and sold to refineries, while gold-bearing fragments are treated with a unique chemical. In just a few minutes, the solution selectively leaches out more than 99% of the gold, which is processed into gold nuggets for recycling. Every year, over 4,400 tons of circuit boards are processed in this way, yielding up to 1000 lb of gold.

Our installation team was one of the first on site. This shows how important our machines and our contribution to this precious metal recovery plant are in supporting The Royal Mint's goals.

Marcus Brew

Managing Director, UNTHA UK