Products

Single-shaft shredder designed to effectively produce coarse, medium, and fine sized end product from a variety of different waste streams

Mobile shredding concept

Sturdy design with high tolerance to contamination

High quality end products with high throughput levels

Low operating costs

Low noise operation

Driving power: 2 x 177 - 2 x 215 hp | 2 x 132 - 2 x 160 kW

Rotor diameter: 39.4" | 1,000 mm

Maximum throughput capacity: 70 t / h

Fraction sizes (based on the screen): 1" - 11.8" | 25 - 300 mm

The efficient UNTHA Eco Power Drive consumes up to 75% less energy than diesel-powered shredders.

We use a Quick Disconnect plug design so you can quickly and safely connect and

disconnect the power supply.

We use a crawler-style track undercarriage powered by an onboard gen-set so the mobile shredder can easily move around the jobsite by remote control.

The XR’s extremely rugged design and superior drive system allow you to easily process waste streams other manufacturers consider “un-shreddable."

The XR3000 mobil-e is a revolutionary breakthrough in mobile waste shredding. It uses the best available electric drive technology while still giving you the on-site and off-site flexibility of a mobile machine.

The Mobil-e does not compromise any of the advantages of the XR Shredder in order to give the flexibility of a mobile unit. The Mobil-e is equipped with the same Eco-Power Drive with water-cooled synchronous motors that is available on the stationary version.

This State-of-the-Art drive system is what separates the UNTHA XR from all the other shredders on the market. It enables the unit to provide a 75% savings in energy costs over diesel powered competitors while still providing superior rotor performance and significantly lower operating cost.

The addition of the track system provides you the most flexible design on the market today. Whether you need a primary, secondary, or tertiary shredder, coupled with the right rotor and gear box drive combination, the XR mobil-e will give you the ability to put it in the most demanding applications without having to worry about whether it will be able to meet and exceed your needs and expectations.

The tracks are powered by an onboard gas-powered 22-HP (20kVa) generator allowing the unit to be moved quickly and easily via remote control. There are three different rotor designs available and the UNTHA Eco-Drive can be equipped with five different gearbox configurations. This allows you to truly customize your XR to meet any processing need whether you need to process the most contaminated bulky wastes or film plastic.

Screen sizes are available in a variety of different hole sizes and configurations to further ensure your machine can process and produce the exact size end product needed for your particular market(s). The discharge conveyor can be equipped with an overband magnet as well as a head pulley magnet to make sure you effectively separate the steel from your final product to satisfy even the most demanding fuel buyer.

These materials can be shredded with the XR mobil-e:

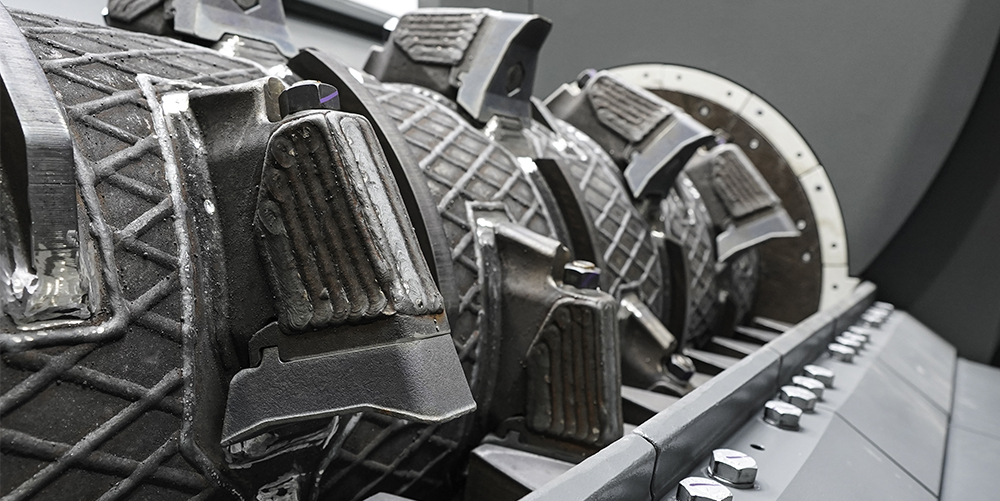

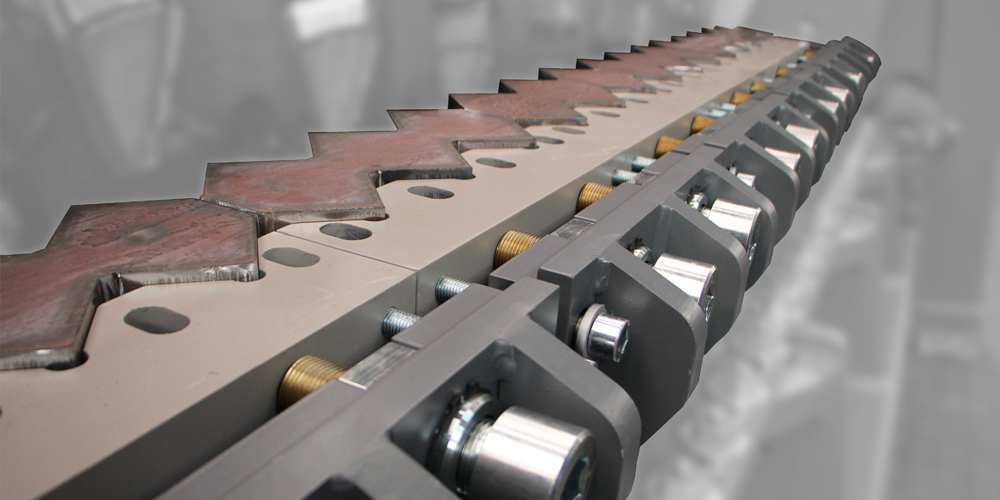

Depending on the material and fraction size, several cutting systems with different blade shapes are available with the RC, C, and XC system. The cutting systems allow fraction sizes from 25 to 300 mm.

The RC cutting system was specifically developed for the coarse pre-shredding of different material flows and for high throughput rates of up to 70 t/h. The purpose-built shape of the blades ensures a particularly aggressive intake behaviour for the material. The cutters and the stator bar may be welded on again at the end of the service life.

Obtainable fraction sizes: 100 - 300 mm

Thousands of customers from diverse industries around the world already place their trust in the reliable UNTHA name.

The shredder is so flexible that we are able to process not just grade 1 to 3 waste wood, but also grade 4 waste wood. The metal we remove from the wood is sold on to the steel industry.

Thomas Breitsamer

Managing Director

For special requirements, we offer custom-made accessories for this shredder.

We offer different hopper shapes that are exactly adapted to your infeed type. Regardless of whether you need a hopper for a wheel bearing infeed or a hopper with a grabber infeed – we will always have a suitable solution available.