References

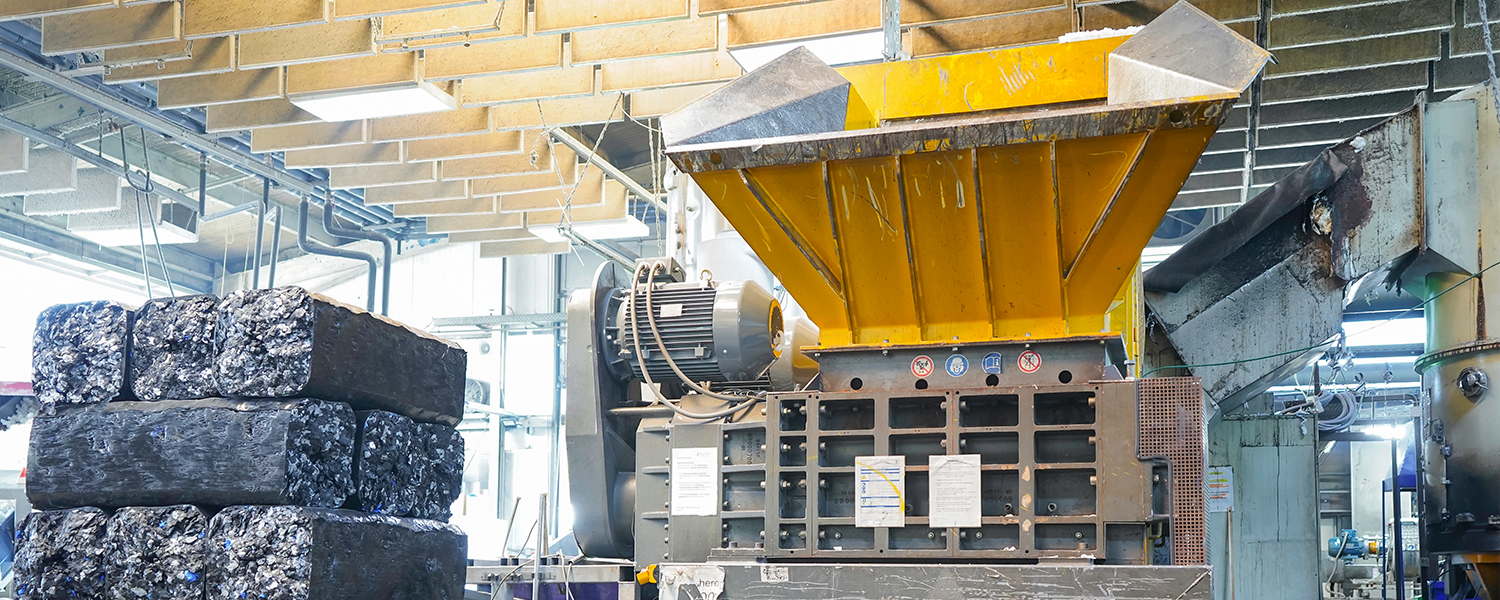

At R.PLAST, two UNTHA RS100 shredders are in use as pre-shredders. These rotor shear systems handle even highly resistant and tear-proof plastics with ease, preparing them for further processing in extruders. The shredders are integrated with conveyor systems that transport materials directly to the next stage of the recycling line. Both units are loaded via forklift.

R.PLAST Kunststoffaufbereitungs- und Handels-GmbH is a specialist in the recycling and trading of primary and secondary thermoplastics. For over 35 years, the company has been transforming plastic production waste into high-quality regrinds, regranulates, and compounds for reuse in various industries.

Processing PE and PP bales, as well as solid plastics, poses a challenge due to their high tear resistance and density. Not all shredders are equipped to handle these tough materials. R.PLAST needed a shredding solution that could quickly and efficiently break down even the most robust plastic waste. Additionally, the new shredders had to be easily integrated into the existing production line.

REQUIREMENTS

Rotor shear-style cutting system

Efficient, reliable pre-shredding

Ability to adapt to various plastic types

Designed for continuous, multi-shift operation

Following extensive material testing, R.PLAST selected the UNTHA RS100, a four-shaft shredder equipped with a rotor shear cutting system. This design is ideal for processing tear-resistant and bulky materials and remains unaffected by contaminants. An optional back-pressure system ensures even tightly packed bales and plastic rolls are efficiently gripped and shredded. The RS100 can operate with or without a perforated screen, depending on material requirements. Screens can also be retrofitted or swapped for added flexibility. At R.PLAST, two RS100 units are used as pre-shredders in continuous multi-shift operation. The shredded plastics are then fed into extruders, where they are converted into granulate for use in injection molding and the automotive industry.

UNTHA performed test runs with our materials and the RS100, and the results were phenomenal. It became clear this was the right shredder for us. We now use two UNTHA RS100s as pre-shredders at the start of our recycling process.

Rolf Treutlein

Managing Director & Partner, R.PLAST Kunststoffaufbereitungs- und Handels-GmbH

For the protection of your personal data the connection to YouTube has been blocked.

Click the button to remove the blocking of YouTube.