Products

The rugged wood shredder for continuous operation

Heavy duty machine construction

Small footprint

Reliable and low maintenance

Low noise and dust emissions

Customized system solutions

Rated capacity: 2 x 7. 4 / 2 x 10 / 2 x 14.8 hp | 2 x 5.5 / 2 x 7.5 / 2 x 11 kW

Feed opening: 17.7" x 22" | 450 x 560 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Maximum throughput capacity: 3 srm/h

Rated capacity: 2 x 20 / 2 x 25 hp | 2 x 15 / 2 x 18,5 kW

Feed opening: 18.9" / 29.5" / 37.8" x 27.5" | 480 / 750 / 960 x 700 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Maximum throughput capacity: 7 srm/h

The RS30 and RS40 wood shredders are mainly used in the wood processing and utilisation industry as well as in large joinery and carpentry establishments. The reliable and highly sturdy four shaft shredders have been tested and proven over several decades, and are used in particular for processing long, solid timber pieces. The shredders can be used as a stand-alone solution or integrated into complex plants. The machines are characterised by their high availability and, thanks to their high throughput, unique productivity.

The four shaft cutting system can be individually adapted to the input material, making this technology ideal for processing materials like bark, wet wood, cardboard and

waste wood with metal inclusions. Due to its extremely compact footprint, the four shaft shredder is suitable for the decentralized disposal of wooden parts directly to the production machines. In addition, it is especially designed for continuous operation in producing wood chips due to its rugged construction. The low maintenance required and the high durability ensure that the operating costs of the shredder remain particularly low.

The high reliability of the RS30 and RS40 wood shredder is a result of their solid cast-iron frame design and the sturdy cutting unit. The low-speed four shaft shredders are also resistant to foreign objects and low maintenance. Thanks to the pull-in mechanism, the machine does not need a hydraulic pusher system, which further reduces the need for maintenance on the wood shredder. The low cutting shaft speed ensures little noise and dust pollution as the wood is shredded.

The RS class shredders for wood are particularly productive due to their high torque in connection with the large perforated screen surface, and are widely used in shift operation at joinery, carpentry, and wood working companies. In case a foreign object is detected, the shredder switches off automatically, protecting against major damage to the cutters. In addition, the wood shredder has been equipped with an automatic reverse function to

prevent motor overload.

The wood shredder models RS30 and RS40 can cope easily with solid wood (long parts, splinter wood), sawmill waste, off-cuts, trimmed parts, veneers, cardboard/paper (mixed with wood), softwood bark, and much more.

Test this shredder with your own materials in our state-of-the-art test centre. Alternatively, we will take our wood shredder to your premises and you may test the machine in real-life operating conditions.

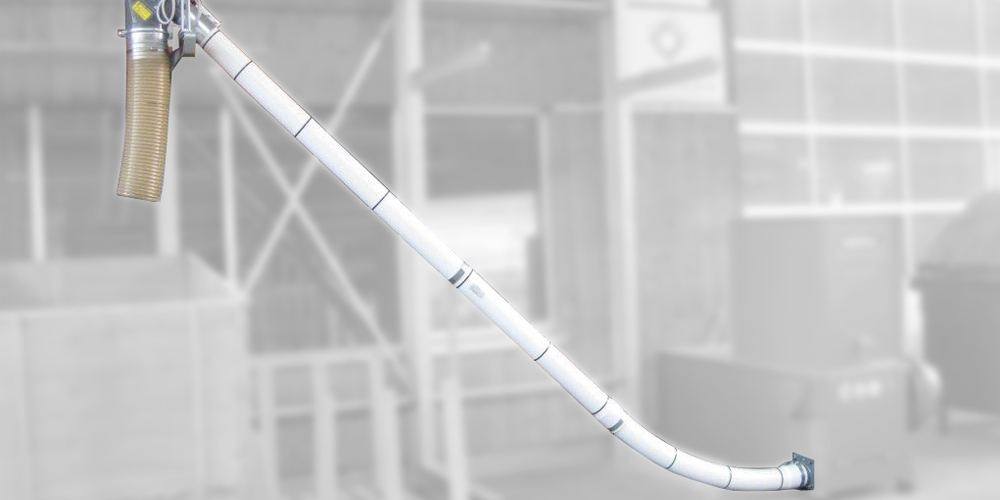

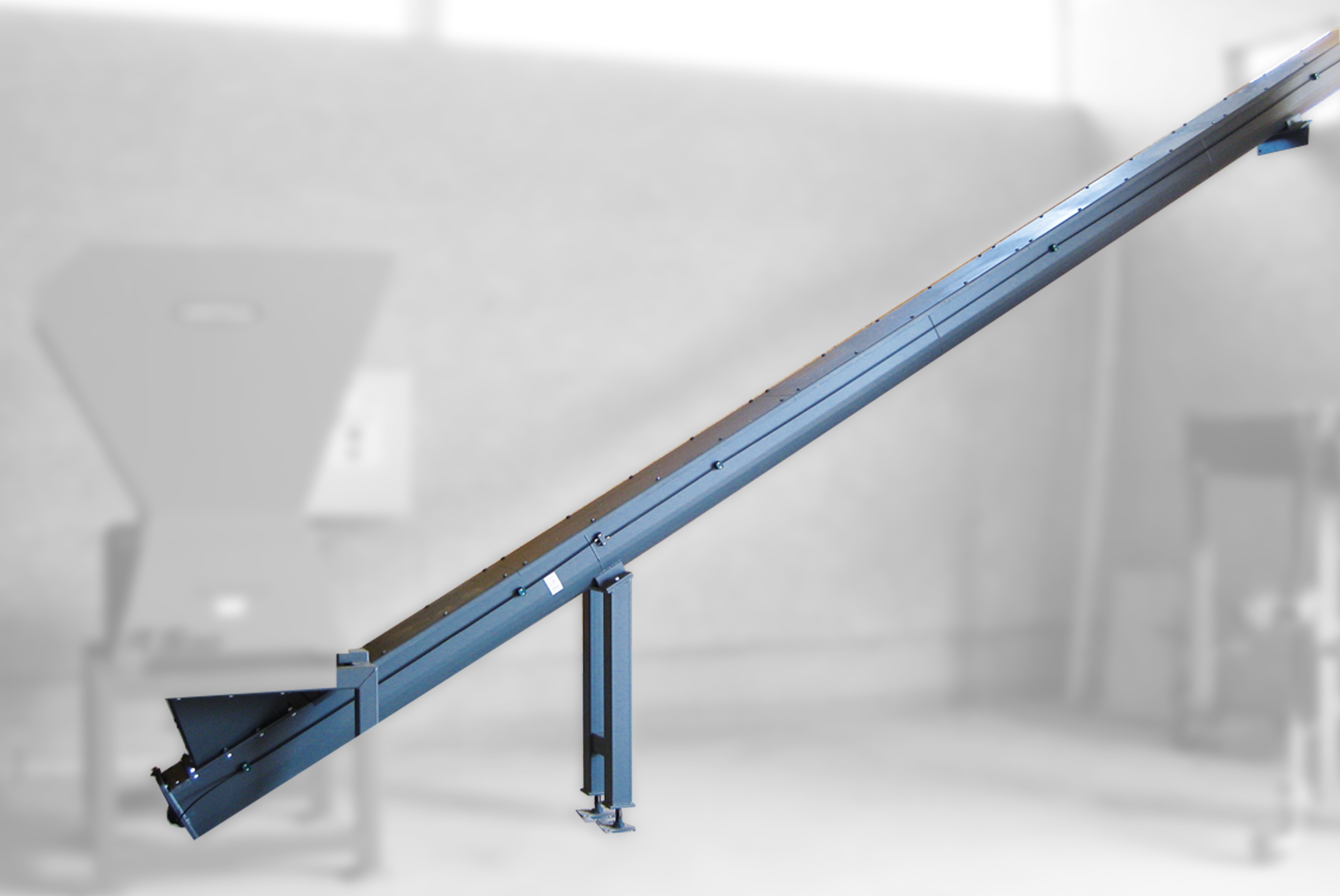

Depending on your requirements, we offer custom-made accessories for this shredder.

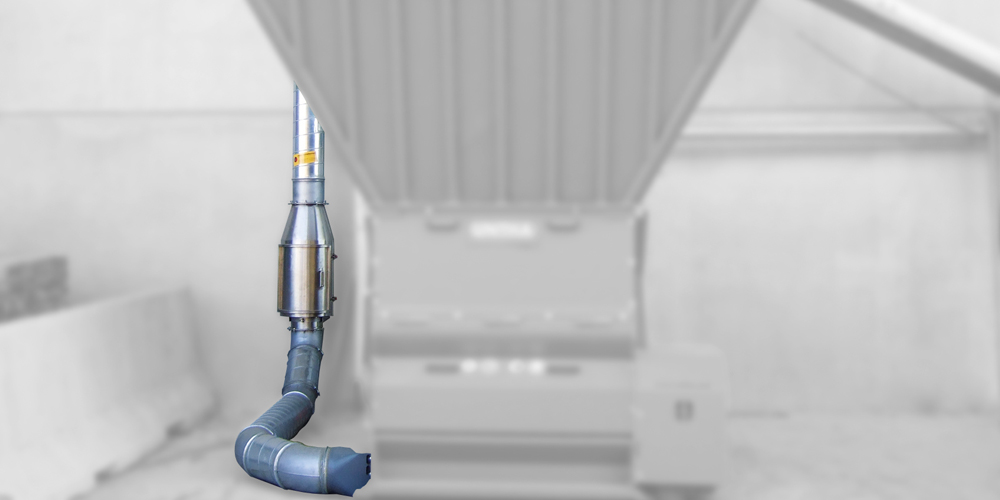

Shredding residual timber with nails or screws is no problem for our shredders. Pipe magnets are commonly used in extraction situations to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.