Leading US supplier of industrial shredders!

Industrial waste shredding solutions for more than 50 years

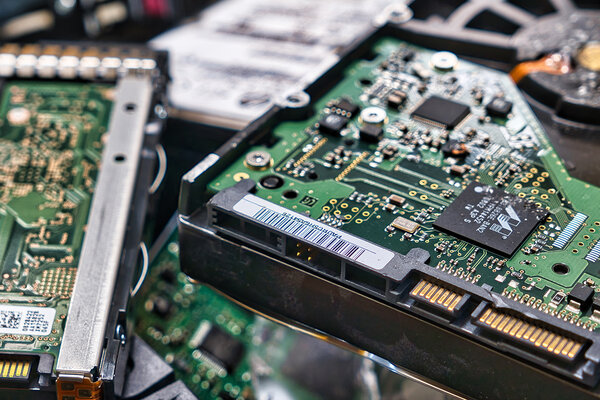

UNTHA America helps you to find the perfect industrial shredder for waste processing, volume reduction, material recycling, and data destruction. Our shredders are powerful, totally reliable and process a wide variety of materials including C&I waste, bulky waste, MSW, metal scrap, tires, hazardous waste, hard drives, electronic waste (WEEE), wood waste, and much more. We offer 1-, 2- and 4-shaft shredding machines customized to your requirements, throughput rate, and desired granulate size. Our machines are durable, low-maintenance, and in daily use at leading companies in the recycling and waste disposal industry. More than 10,000 customers worldwide already rely on our efficient and reliable shredding solutions.

Material

Wood as production waste accumulates in numerous companies, from carpentry businesses to the packaging industry. Through shredding, a secondary fuel can be generated for numerous applications. Regardless of how you are planning to use the wood chips, we will configure the residual timber shredder exactly according to your needs.

Products

Discover the world of reliable shredding solutions

From commissioning to hard surfacing, cutter changes, and regular inspection and maintenance activities, we look after your industrial shredder throughout its lifetime.

Here you can read what our customers have to say about their successful experience of working with UNTHA and about our outstanding products.

We needed a shredder that could handle our growing volume without compromising quality or efficiency. The UNTHA RS100 has exceeded our expectations, delivering exceptional throughput, reliability, and ease of maintenance. This investment has been a game-changer for our operations.

Adam Shine

President of Sunnking Sustainable Solutions